Wheel ceramic coatings protect vehicles from environmental damage, preventing corrosion and enhancing aesthetics with a durable, glossy finish. Their multi-layered structure offers superior resistance to scratches, chips, and fading, while breathable properties prevent rust formation. Studies show extended corrosion prevention, especially against road salt, when properly applied. Professional installation techniques enhance heat rejection and oxidation protection. Accessible for everyday drivers, proper maintenance ensures long-lasting scratch protection and preserves curb appeal.

“Uncover the power of wheel ceramic coating as a long-term corrosion prevention solution. This comprehensive guide explores how this advanced technology shields your vehicle’s wheels, enhancing aesthetics and structural integrity. From understanding its basic functionality to real-world applications, we delve into research highlighting its durability. Learn essential maintenance tips to ensure optimal performance and protect your wheels from the elements. Discover why wheel ceramic coatings are a game-changer for long-lasting, corrosion-free wheels.”

- Understanding Wheel Ceramic Coating's Basic Functionality

- Longevity and Durability: What Research Says

- Real-World Applications and Maintenance Tips

Understanding Wheel Ceramic Coating's Basic Functionality

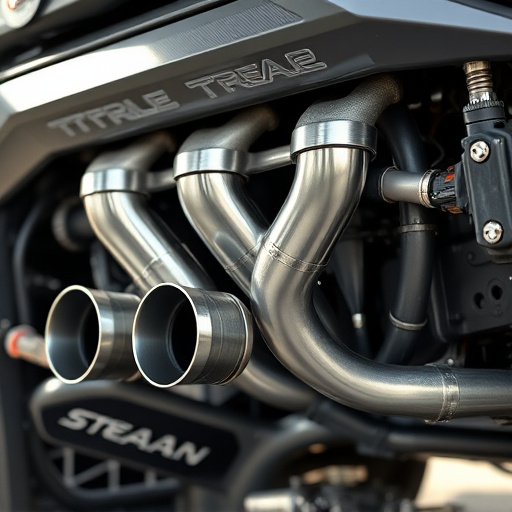

Wheel ceramic coating is a protective layer designed to safeguard your vehicle’s wheels from various environmental elements that can lead to corrosion over time. By understanding its basic functionality, we can grasp why it has become an increasingly popular choice among automotive enthusiasts and professionals in the detailing industry. This innovative technology creates a barrier between the metal wheel surface and potential corrosive agents such as road salt, bird droppings, and acid rain.

The coating forms a durable, glossy finish that not only enhances the aesthetic appeal of the wheels but also provides long-lasting protection. Its multi-layered structure comprises advanced ceramic particles embedded in a resin matrix, offering exceptional resistance to scratches, chips, and fading. Moreover, wheel ceramic coatings are known for their breathability, allowing moisture to escape while preventing rust formation, making them an excellent solution for all-weather protection, especially when combined with other protective layers like paint protection film or vehicle wraps for comprehensive automotive detailing.

Longevity and Durability: What Research Says

The durability of a wheel ceramic coating has been a topic of interest for automotive enthusiasts and professionals alike. Numerous studies have explored the long-term effects of this innovative protection method, with promising results. Research indicates that a well-applied wheel ceramic coating can withstand various environmental challenges, offering significant corrosion prevention over extended periods.

A key advantage lies in its ability to protect against road salt, a common accelerant for corrosion. The hard ceramic layer acts as a barrier, preventing the penetration of corrosive substances, which is crucial for maintaining high-quality finishes. Moreover, professional PPF (Paint Protection Film) installation techniques, when combined with ceramic coatings, can enhance heat rejection and provide an extra layer of defense against oxidation, ensuring wheels retain their luster even in harsh conditions.

Real-World Applications and Maintenance Tips

In real-world applications, wheel ceramic coatings have proven to be highly effective in preventing corrosion and enhancing the overall look of vehicles. This advanced coating technology is not limited to just show cars or high-end models; it’s accessible for everyday drivers looking to add a layer of protection and customization to their ride. Many car enthusiasts and professionals in the automotive industry are turning to wheel ceramic coatings as a part of their vehicle enhancement routine, considering it a cost-effective solution for long-lasting scratch protection.

When it comes to maintenance, proper care is essential to keep the coating’s effectiveness intact. Regular cleaning and conditioning are crucial, especially when dealing with environmental factors like salt, acid rain, or harsh chemicals used in car washes. Using dedicated ceramic coating cleaners and microfibers ensures that the surface remains pristine. Additionally, avoiding extreme temperature changes and direct contact with abrasive materials can significantly extend the life of the wheel ceramic coating, providing years of corrosion-free driving experience and preserving the vehicle’s curb appeal through effective car customization techniques.

Wheel ceramic coatings have proven to be an effective long-term solution against corrosion, as backed by both research and real-world applications. Their durability, combined with proper maintenance, ensures wheels remain protected and looking pristine for years. As the market for wheel ceramic coatings continues to grow, understanding their functionality and benefits becomes essential for vehicle owners seeking reliable protection against corrosive elements.